Sea Storm Glass by Cardinal Glass provides the ultimate protection for your home. The tremendous strength of Cardinals laminated glass delivers the optimum protection from both hurricanes and tornados. Sea Storm Glass also provides security defense by keeping thieves out when you are away from your home.

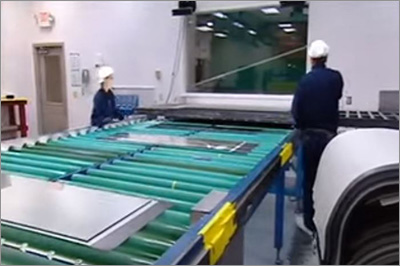

After seeing the damage incurred from the two most recent storms to strike the USA, Hurricane Florence & Hurricane Michael, I thought we would take a look at how Cardinal manufactures its Sea Storm Glass. Take a moment to watch the video below to get a first-hand look at the entire manufacturing process.

The Sea Storm Glass Manufacturing Process

If you watched the video, you learned how Cardinal has developed and perfected the Laminated Glass manufacturing process to provide superior service and unmatched quality for all of its customers. The video demonstrates the step by step procedure Cardinal follows to produce premium laminated glass.

The first step in the process is to load the glass on to the production line using a robotic arm equipped with pneumatic suction cups. The glass panels used in the construction of laminated glass can be annealed, strengthened, or tempered depending on the end product.

In a clean room adjacent to the line, Cardinal associates cut the interlayer to the appropriate size to match the production run. The clean room is both temperature and humidity controlled to reduce marring and eliminate debris that could otherwise be trapped inside the final product.

The glass panel travels along a roller conveyor. When the glass lites enter the clean room, the process operators attached the pre-cut interlayer to the top side of one of the panels. They then place another glass lite on top of the interlayer to create a sandwich. The assembly then passes through an oven to heat the glass, at the same time any air is pressed out. At this stage of the process the glass panel is opaque in color.

The next step is to place the panel into a computer-controlled autoclave. While inside the autoclave, the glass is heated as the chamber is pressurized to bond the interlayer to the glass. The assembly is transformed into a clear glass sheet during the 2 to 4 hour cycle.

Sea Storm Glass Testing

Cardinal conducts regular testing of the Sea Storm Glass product to determine the structural capabilities of the glass. The lab replicates the actions of flying debris that is common during hurricanes and tornados. Both sides of the glass are subjected to wind speeds of up to 180 miles per hour. Additional tests are conducted to assess the strength of the glass when subjected to an attempted forced entry.

The Benefits of Cardinals Laminated Glass:

- Safety: The additional strength of Cardinals Laminated Glass can keep flying debris from entering your home during a storm.

- Security: Laminated glass cannot be cut from one side only, therefore criminals can’t use a cutting tool to gain access to your home.

- Noise Abatement: If you live near an airport, busy street, or highway, installing laminated glass can dramatically reduce the annoying noise from these sources.

- UV Reduction: Cardinal LG products can reduce the intrusion of Ultra Violet Rays, which will otherwise fade carpets and furniture over time.

Interested in installing Sea Storm Glass in your home or office? Contact our support team at (815) 634-8922.